WPS Slow-running single shaft shredder

WPS Slow-speed single-shaft shredders are versatile machines designed for the efficient processing of a wide range of materials, including plastics, wood, and industrial waste. Their low speeds and high torque provide quiet and efficient operation. They are suitable for recycling bulky plastic parts such as barrels, pallets, or pipes.

SOLLAU CZ: Exclusive representation of WOBIDE mills and crushers for the Czech Republic, Slovakia and PL!

Their robust design ensures a long life and reliable operation. The PJS series pre-shredders can be adapted to specific applications, allowing the recycling process to be optimized.

Slow-running shredders are available from 409.000 CZK - reliable performance, fast service, and available spare parts!

The WPS series of high-speed mills offer an excellent price/performance ratio. However, this does not mean a compromise in quality. It has 30 years of experience in the plastics recycling industry and a professional approach at all levels of the production process that speak for themselves.

- All shredders are manufactured under strict European standards, as evidenced by CE certification and production acc. to ISO 9001 standards.

- Key components such as control electronics are sourced exclusively from renowned European manufacturers Schneider and ABB, guaranteeing long-term reliability and trouble-free operation of the shredders.

Rotor to-measure

Rotor to-measure

The crusher is designed with different shaft configurations to suit specific material types.

- For soft materials such as foils and large bags, the W-shaft is used.

- Rotor shaped like a blade for block material (blade seats are robustly welded to prevent material from entering the gaps; this prevents corrosion of the bolts and facilitates future maintenance).

Changing the rotor angle

Changing the rotor angle

The rotor can be reused by changing the angle according to the wear condition, which can result in significant cost savings.

Hydraulic opening system

Hydraulic opening system

Maintenance time can be saved by using a hydraulic system that allows quick sieve exchange.

6 + 1 Reasons to Choose the WPS Low-Speed Mill

We use first-class alloy steel. Key components prone to wear and tear undergo heat treatment and wear-resistant coating for increased durability.

The integrated hydraulic system simplifies sieve changes and allows easy opening and closing of the machine body. It also provides quick access for cleaning and changing blades.

The control system includes high-end Schneider/ABB components for the basic electrical elements and Mitsubishi/Siemens PLC for automation. The system features automatic polarity reversal of the shaft in the event of overload, offering increased protection for the equipment. The intuitive one-touch Start/Stop function simplifies attendance. The hydraulic pressure and pressure ram speed can be easily adjusted via the central hydraulic station, reducing operator skill requirements and optimizing performance.

WPS high-speed mills offer excellent prices without compromising on quality, making them the ideal solution for demanding plastic recycling applications.

The shredding chamber construction is designed for maximum efficiency. The integrated suspension and pressure ram guide rails reduce wear and the flat-bottom chamber design minimizes the cost of replacing parts. The tilting chamber configuration improves material feed, promoting smoother shredding and increased performance.

The bearings are mounted externally to prevent their contamination. The bearing seats are sealed with sealing rings. This effectively prevents material ingress and significantly extends bearing life by reducing the risk of damage from foreign particles.

Both the rotor and stator blades are made from D2 or DC53 steel, which is more wear-resistant and has a longer lifetime than conventional spring steel. This ensures consistent cutting performance for a longer period.

WPS shredders are available in several variants according to the capacity and customer requirements:

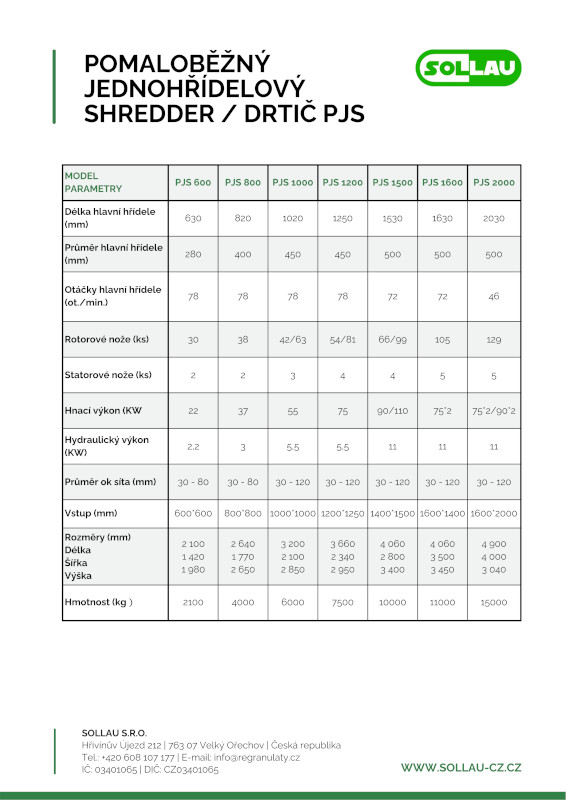

| Model Parameters | WPS 600 | WPS 800 | WPS 1000 | WPS 1200 | WPS 1500 | WPS 1600 | WPS 2000 |

|---|---|---|---|---|---|---|---|

| Main shaft length (mm) | 630 | 820 | 1020 | 1250 | 1530 | 1630 | 2030 |

| Main shaft diameter (mm) | 280 | 400 | 450 | 450 | 500 | 500 | 500 |

| Main shaft speed (rpm) | 78 | 78 | 78 | 78 | 72 | 72 | 46 |

| Rotor knives (pcs) | 30 | 38 | 42/63 | 54/81 | 66/99 | 105 | 129 |

| Stator knives (pcs) | 2 | 2 | 3 | 4 | 4 | 5 | 5 |

| Driving power (KW | 22 | 37 | 55 | 75 | 90/110 | 75*2 | 75*2/90*2 |

| Hydraulic power (KW) | 2,2 | 3 | 5,5 | 5,5 | 11 | 11 | 11 |

| Sieve mesh diameter (mm) | 30 - 80 | 30 - 80 | 30 - 120 | 30 - 120 | 30 - 120 | 30 - 120 | 30 - 120 |

| Input (mm) | 600*600 | 800*800 | 1000*1000 | 1200*1250 | 1400*1500 | 1600*1400 | 1600*2000 |

| Dimensions (mm)Length Width Height |

2 100 1 420 1 980 |

2 640 1 770 2 650 |

3 200 2 100 2 850 |

3 660 2 340 2 950 |

4 060 2 800 3 400 |

4 060 3 500 3 450 |

4 900 4 000 3 040 |

| Weight (kg) | 2100 | 4000 | 6000 | 7500 | 10000 | 11000 | 15000 |

- Main shaft length: 630 (mm)

- Driving power: 22 kW

- Inlet opening: 600 x 600 mm

- Capacity: 300 – 3,000 kg/h

The main parameters of the WPS 600 slow-running single-shaft shredder.

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WPS 600 | 630 | 280 | 78 | 30 | 2 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm) | Dimensions (L*W*H)(mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WPS 600 | 22 | 2,2 | 30-80 | 600*600 | 2100*1420*1980 | 2 100 |

- Main shaft length: 820 mm

- Driving power: 37 kW

- Inlet opening: 800 x 800 mm

- Capacity: 300 - 3,000 kg/h

The main parameters of the WPS 800 slow-running single-shaft shredder.

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WPS 800 | 820 | 400 | 78 | 38 | 2 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm) | Dimensions (L*W*H)(mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WPS 800 | 37 | 3 | 30-80 | 800*800 | 2640*1770*2650 | 4 000 |

- Main shaft length: 1,020 mm

- Driving power: 55 kW

- Inlet opening: 1,000 x 1,000 mm

- Capacity: 300 - 3,000 kg/h

The main parameters of the WPS 1000 slow-running single-shaft shredder.

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WPS 1000 | 1 020 | 450 | 78 | 42/63 | 3 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm) | Dimensions (L*W*H)(mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WPS 1000 | 55 | 5,5 | 30-120 | 1000*1000 | 3200*2100*2850 | 6 000 |

- Main shaft length: 1,250 mm

- Driving power: 75 kW

- Inlet opening: 1,200 x 1,250 mm

- Capacity: 300 - 3,000 kg/h

The main parameters of the WPS 1200 slow-running single-shaft shredder.

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WPS 1200 | 1 250 | 450 | 78 | 54/81 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm) | Dimensions (L*W*H)(mm) | Weight (kg) | WPS 1200 | 75 | 5,5 | 30-120 | 1200*1250 | 3660*2340*2950 | 7 500 |

|---|

- Main shaft length: 1,530 mm

- Driving power: 90/110 kW

- Inlet opening: 1,400 x 1,500 mm

- Capacity: 300 – 3,000 kg/h

The main parameters of the WPS 1500 slow-running single-shaft shredder.

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WPS 1500 | 1 530 | 500 | 72 | 66/99 | 4 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm) | Dimensions (L*W*H)(mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WPS 1500 | 90/110 | 11 | 30-120 | 1400*1500 | 4060*2800*3400 | 10 000 |

- Main shaft length: 1,630 mm

- Driving power: 2 x 75 kW

- Inlet opening: 1,600 x 1,400 mm

- Capacity: 300 - 3,000 kg/h

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WPS 1600 | 1 630 | 500 | 72 | 105 | 5 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm) | Dimensions (L*W*H)(mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WPS 1600 | 75*2 | 11 | 30-120 | 1600*1400 | 4060*3500*3450 | 11 000 |

- Main shaft length: 2030 (mm)

- Driving power: 2 x 575/2 x 90 kW

- Inlet opening: 1600 x 2000 mm

- Capacity: 1000-1500 kg/h

The main parameters of the WPS 2000 slow-running single-shaft shredder.

| Model | Main shaft length (mm) | Main shaft diameter (mm) | Main shaft speed (rpm) | Rotor knives (pcs) | Stator knives (pcs) |

|---|---|---|---|---|---|

| WPS 2000 | 2 030 | 500 | 46 | 129 | 5 |

| Model | Driving power (KW) | Hydraulic power (KW) | Sieve mesh diameter (mm) | Input (mm) | Dimensions (L*W*H)(mm) | Weight (kg) | WPS 2000 | 75*2/90*2 | 11 | 30-120 | 1600*2000 | 4900*4000*3040 | 15 000 |

|---|

Dimensional table of WPS Slow-running single shaft shredders

Dimensional table of WPS Slow-running single shaft shredders

Download PDF

(size 179 kB)