Self-cleaning pipeline magnetic separators MSP-AC

Magnetic separator MSP-AC for pipeline transport with automatic cleaning is designed to separate in a quick and easy way the magnetic iron contamination from free-flowing liquid or powder substances of good bulk properties.

How does flow-liquid magnetic separator work?

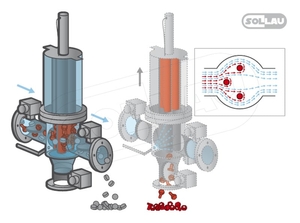

The basic elements the magnetic grate separator consists of are vertical magnetic tubes made from stainless steel. The grate labyrinth - created in this way – is in a very intensive contact with the flowing material and can capture even the smallest ferromagnetic impurities and guarantees an extremely high separation efficiency. Our magnetic separator MSP-AC is fitted with extremely strong neodymium NdFeB magnets (generating a magnetic induction up to 10.500 Gs on the magnetic tube surface) in order to achieve the best separation results.

Which way is flow-liquid separator cleaned?

During the automatic cleaning the magnetic cores are pulled out of the stainless tubes and the ferromagnetic particles are washed off the magnetic tubes. in order to achieve the best separation results. In order to make the best possible (economical and ecological) use of the rinsing water, we can fit the rinsing circuit with an additional magnetic separator (separating the captured ferromagnetic parts from the rinsing liquid and allowing for a repeated use of the rinsing liquid inside of the magnetic separator MSP-AC). The automatic cleaning is carried out by pneumatic cylinders (moving the magnet rods) and managed by a pre-programmed control unit. A touchscreen control panel arranges for a rapid and individual adjustment of the magnetic separator to the actually needed use.

Further advantages of self-cleaning pipeline magnetic separator MSP-AC

This kind of separator can be delivered also in a double wall jacketed version. The double jacketed filters are used in heated pipeline applications where the temperature is critical to the product viscosity (i. e., the separator tempering prevents the cleaned products - such as chocolate, syrups, jams, sauces - from solidifying).

Which industrial branches can the flow-liquid magnetic separator be use of in?

Magnetic separator MSP-AC for pipeline transport (with automatic cleaning) is designed to handle heavy contamination at inconvenient locations and can be integrated in a fully automatized production line, what ensures a high effectiveness of the production process. Magnetic separator MSP-AC for pipeline transport (with automatic cleaning) finds use in engineering as well as in sugar, food, pharmaceutical, chemical and ceramic industries.

Strojírenský a slévárenský průmysl

Keramický a sklářský průmysl

Chemický průmysl, nátěrové hmoty

Automobilový průmysl

Potravinářský průmysl

What pipeline is the separtor connected to?

In order to ensure a quick and easy connection, the separator housing is standardly ended by flanges (standard type, Jacob quick-connect fasteners or flanges according to client's needs) in sizes from 50 to 250 mm (but we can adjust the connection type as well as its size to client's requirements).

MSP-AC

Is designed to separate in a quick and easy way the magnetic iron contamination from free-flowing liquid or powder substances of good bulk properties.

| Product | Connecting diameter (mm) |

Datasheet (CZ) |

|---|---|---|

| MSP-AC 50 N | 50 | display PDF |

| MSP-AC 100 N | 100 | display PDF |

| MSP-AC 150 N | 150 | display PDF |

| MSP-AC 200 N | 200 | display PDF |

| MSP-AC 250 N | 250 | display PDF |